Groundwater inflow is one of the biggest challenges on WA mine sites. Without proper dewatering, open pits flood rapidly, delaying haulage and equipment access.

Our experts at Silverstone have prepared this dewatering guide to explain what dewatering is and why it matters. It also outlines the methods and best practices that mine site operations across WA are safe, compliant, and on track.

What Is Dewatering?

Dewatering removes groundwater and surface water from active mine sites to maintain safe, dry, and stable working conditions. In mining, it supports excavation, heavy equipment operation, and pit stability by lowering groundwater levels. Without effective dewatering, mine operations face costly delays, safety hazards, and equipment damage.

Groundwater can quickly flood open pits and haul roads, halting production. Bore and transfer pumps with HDPE pipelines remove and redirect water to keep operations safe. Reinjection systems return treated water to aquifers, maintaining compliance and groundwater balance. WA holds over 200 dewatering licences, mostly linked to mine operations extracting 300 gigalitres annually.

Construction projects also rely on dewatering, though on a smaller scale. Deep excavations, tunnels, and foundations need controlled groundwater removal to maintain stability. Mine dewatering, however, is far more complex, requiring durable infrastructure and continuous monitoring in WA’s harsh conditions.

Why Dewatering Matters for Mine Site Project Managers

Managing water on a mine site is never optional. Effective dewatering safeguards production, safety, and compliance across every stage of operations.

- Preventing pit flooding and costly delays: Bore and transfer pumps remove groundwater that can halt mining and damage haul roads.

- Maintaining safety and access: Controlled dewatering keeps benches and ramps dry, preventing equipment bogging and slope instability.

- Protecting equipment and infrastructure: HDPE pipelines, electrical cabling, and pumps perform reliably only in stable, dry conditions.

- Supporting compliance and sustainability: Reinjection systems return treated groundwater to aquifers, helping sites meet DWER and EPA standards.

Common Dewatering Methods & When to Use Them

| Method | Description | Ideal Conditions | Pros/Cons |

| Wellpoint Systems | A series of small wells connected to a vacuum pump | Shallow excavations, sandy soils | Efficient but less effective in clays |

| Sump Pumping | Pumps collect water in sumps at the excavation base | Short-term, small-scale excavations | Simple, low cost; limited capacity |

| Deep Well Systems | Boreholes with submersible pumps draw water down | Large excavations, high groundwater levels | Handles high volumes; higher setup cost |

| Eductor Systems | High-pressure water lowers groundwater via ejectors | Low-permeability soils | Effective in silts; energy-intensive |

| Passive Drainage | Gravity-based drains and pipes | Long-term, sloping terrain | Low maintenance; slow and site-dependent |

Key Factors to Consider Before Mine Dewatering

Every mine site needs a tailored dewatering plan suited to geology, pit depth, and production goals. Soil type, aquifer yield, and groundwater levels determine bore spacing, pump capacity, and discharge flow. Long-term operations rely on durable HDPE pipelines, flexible risers, and corrosion-resistant fittings for consistent performance.

Environmental impact is equally important. Teams must assess discharge points, reinjection options, and water quality before installation. Choosing the right diesel, electric, or submersible bore pumps depends on site logistics and available power. Transfer pumps must handle variable flow rates as pits expand to maintain continuous operations.

Compliance and Environmental Considerations in WA

Mine dewatering in Western Australia operates under strict environmental and licensing rules. Projects must meet DWER requirements under the Rights in Water and Irrigation Act 1914 and the Water Services Act 2012. These laws protect groundwater systems and promote sustainable extraction.

Sites that discharge or reinject water require approved dewatering licences confirming volumes and water quality. If inflows contain metals, hydrocarbons, or salinity, teams install treatment and filtration systems before reuse or reinjection. Reinjection bores maintain aquifer balance and reduce drawdown impacts on nearby users.

Regular water sampling and monitoring confirm compliance with EPA guidelines and licence conditions. Strong monitoring programs prove responsible management and safeguard access to groundwater resources vital for mining operations.

Dewatering Equipment Options

Reliable equipment keeps mine dewatering systems efficient and compliant across WA’s harsh conditions. Bore pumps, transfer pumps, and HDPE pipelines must suit groundwater depth, flow rate, and site layout. Diesel, electric, and submersible pumps each deliver specific power and capacity advantages for pit dewatering and reinjection systems.

Heavy-duty HDPE pipelines, flexible risers, and reinforced hoses deliver durability and abrasion resistance on mine sites. Filtration systems remove silt and contaminants before discharge or reinjection, protecting equipment and meeting standards. Silverstone provides rental options for bore pumps, transfer units, and HDPE assemblies to keep projects reliable and cost-efficient.

Best Practices for Successful Dewatering

Effective dewatering starts with preparation. A detailed hydrogeological assessment defines soil conditions, groundwater levels, and environmental risks before work begins. This information helps project managers select the right bore pumps, transfer systems, and HDPE layout for consistent performance.

Planning must also cover unexpected inflows and equipment faults. Backup pumps and flexible HDPE connections keep operations running when conditions shift. Routine maintenance of pumps, risers, and filtration systems prevents failures, reduces downtime, and extends equipment life across demanding WA mine sites.

Learn more: Sustainable Water Solutions for Remote and Harsh Environments.

Case Study: Dewatering Success on a WA Mining Site

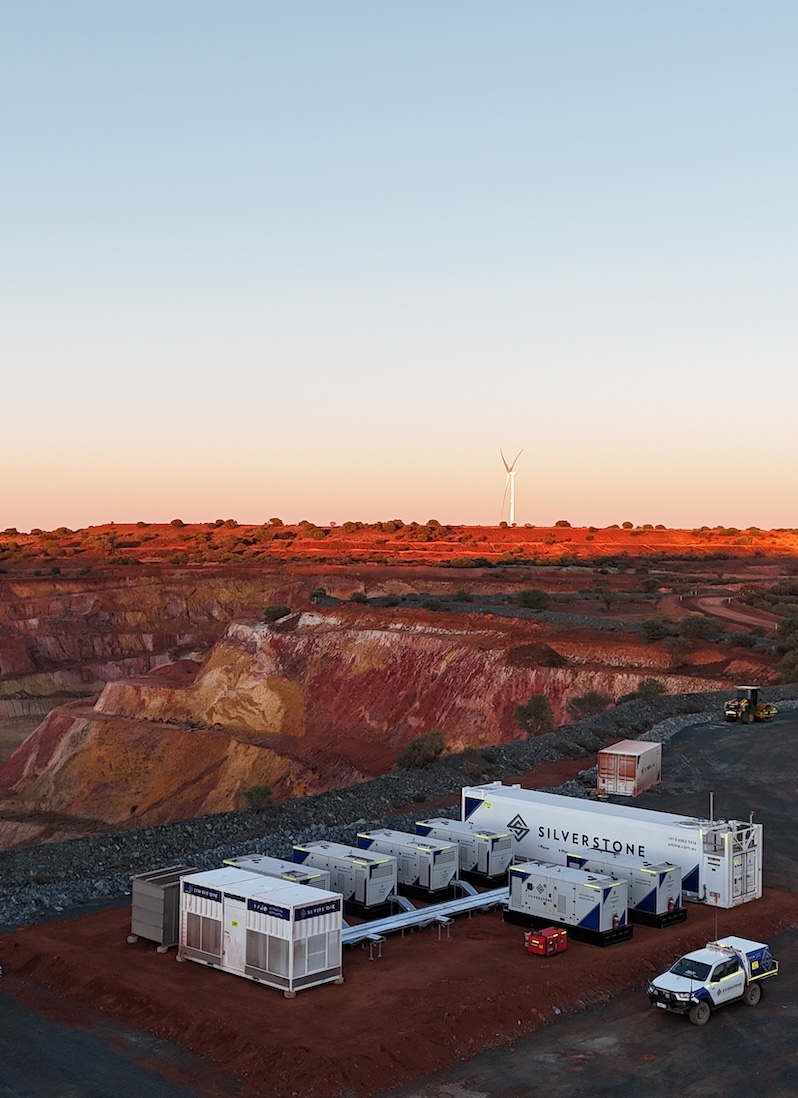

A major Pilbara project required rapid in-pit dewatering infrastructure. Silverstone supplied, transported, installed, tested, and commissioned downhole equipment and trailer-mounted headworks packages.

Challenges: High groundwater inflows threatened excavation progress and equipment reliability. Strict safety and compliance requirements demanded expert execution.

Solutions:

✔ Installed submersible bore pumps with flexible risers, couplings, and borecaps.

✔ Connected mining hoses to trailer-mounted headworks with certified galvanised steel structures.

✔ Integrated electric cabling, control panels, Variable Speed diesel generators, and skid-mounted fuel tanks.

✔ Delivered complete installation and commissioning services, including water-level monitoring instrumentation.

Results: Silverstone delivered critical infrastructure on time and on budget. The project ran incident-free, meeting compliance standards while ensuring continuous operations.

How Silverstone Supports Dewatering Projects

Silverstone brings local WA expertise and end-to-end delivery for dewatering projects. Our teams understand harsh site conditions and strict regulations, designing solutions that are both practical and reliable.

We provide turnkey packages covering design, operations, pumps, piping, and power. Flexible rental and maintenance options reduce upfront costs while keeping equipment reliable throughout the project.

Silverstone also supports compliance, guiding managers through permits, monitoring, and reporting. With a people-first approach, our on-ground teams deliver safe, efficient, and incident-free results.

Keep Mining Projects Moving with Proven Dewatering Solutions

Dewatering is one of the most critical yet overlooked elements of mining and construction planning. A clear dewatering guide helps project managers avoid delays, protect safety, and meet compliance. With WA’s challenging groundwater conditions, proactive consultation with trusted dewatering contractors Perth-wide ensures your project runs smoothly.

Talk to Silverstone today on 08 6365 5416 or email [email protected] to design tailored dewatering solutions that safeguard your site and keep your operations moving.