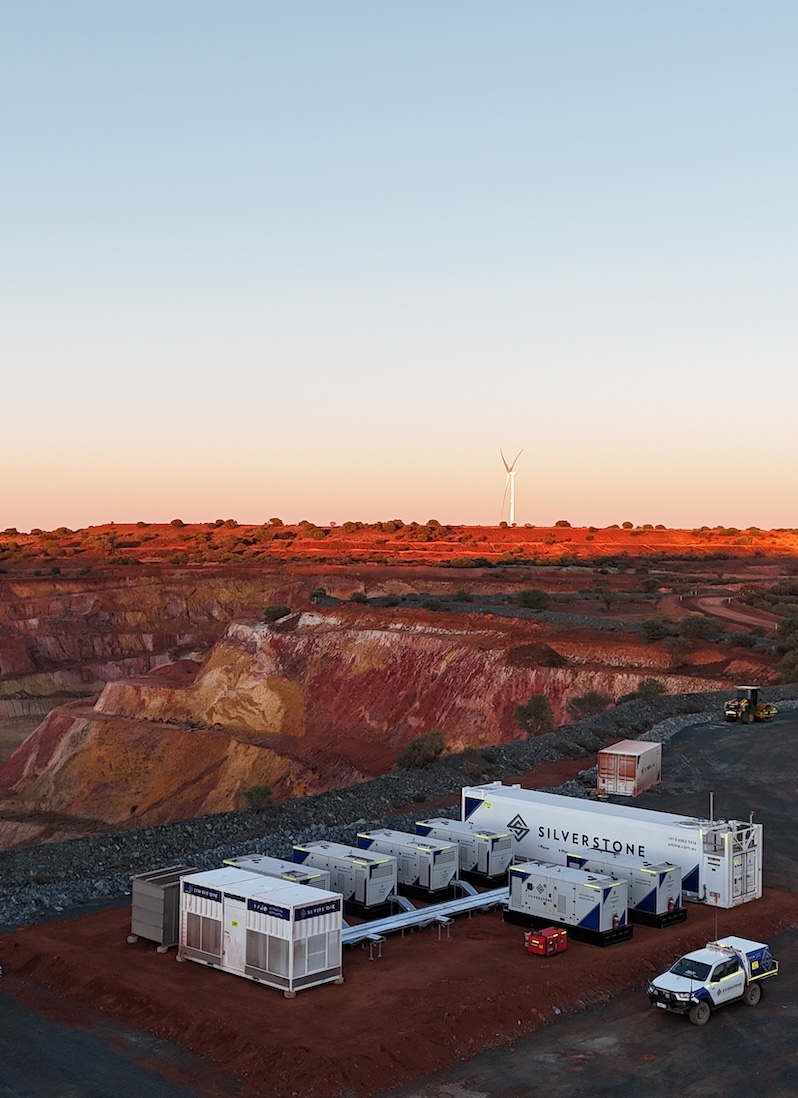

Silverstone

We use the industry's best people to solve mining’s toughest challenges.

Our difference is simple: we only trust people with genuine, hands-on industry experience to deliver our projects. They understand your challenges, solve problems fast, and make informed, real-time decisions that get results.

Our Capabilities

Power

At Silverstone, our power solutions are delivered by professionals with years of hands-on industry experience. We understand the challenges of site conditions, logistics, and high-pressure operations at every stage—from planning and design to execution and ongoing support. Backed by deep technical expertise, vertically integrated capabilities, and a focus on preventative strategies, our team ensures your power remains reliable, efficient, and fully operational whenever and wherever you need it.

Water

At Silverstone, our team brings decades of hands-on experience designing, constructing, supplying, and maintaining water infrastructure that stands the test of time. With reliable water being non-negotiable, we tailor solutions for every site, engineered for performance, efficiency, and longevity. From dewatering systems and pipelines to full-scale water infrastructure, we act quickly while planning for the long term—ensuring your water systems remain operational, efficient, and capable of meeting the demands of 24/7 operations.

Survey

At Silverstone, precision drives everything we do—and our surveying team delivers it every time. Combining industry-leading technology, including advanced UAV drone capabilities, with decades of on-ground experience across Western Australia, our surveyors work seamlessly with clients to keep complex projects moving smoothly. Trusted for their accuracy, problem-solving ability, and practical approach, our team provides efficient, reliable outcomes designed for real-world conditions.

Recruitment

At Silverstone, every candidate is assessed by industry professionals with hands-on experience in the roles they are recruiting for. We understand the realities of the job and the skills that truly matter—never relying on surface-level screening or generic checklists. Our team knows the right questions to ask, and leverages deep industry networks and insider knowledge to ensure the right person is matched to the right role, every time.

Our

Commitment

Silverstone delivers end-to-end solutions across some of Australia’s most demanding sectors, combining technical expertise, rapid response capability, and a zero-harm mindset. We support mining, oil and gas, engineering and construction, utilities, and power rentals with integrated services spanning dewatering, temporary power, civil and electrical works, workforce deployment, and project management. Our teams operate confidently in remote and complex environments, ensuring every project is executed with precision, compliance, and safety at the forefront. With in-house engineering, surveying, and field service capabilities, we provide reliable, scalable, and cost-efficient solutions that keep operations moving and help clients meet both operational and ESG objectives.

Proven Results

Trusted by industry leaders

Latest News

When to Rent vs Buy Power Equipment: A Cost-Benefit Analysis

Power equipment is a significant cost for WA industrial projects. The wrong choice can easily lead to cost overruns, downtime,...

Dewatering 101: What Every Project Manager Should Know

Groundwater inflow is one of the biggest challenges on WA mine sites. Without proper dewatering, open pits flood rapidly, delaying...

Read more

How to Hire the Right People for Remote Mining and Construction Sites

The success of a remote site project hinges on the quality of its people. Seasoned mining managers and recruiters know...

Read more

Mental Health & Well-being in the Mining Industry

Safety Focus: Mental Health & Well-being in the Mining Industry The mining industry is known for its tough working conditions,...

Read more